These pages briefly represent the machineries that make up our production lines called MBM24 and MBM36, which differ from each other in mechanical speed, 2400 and 3600 meters respectively.

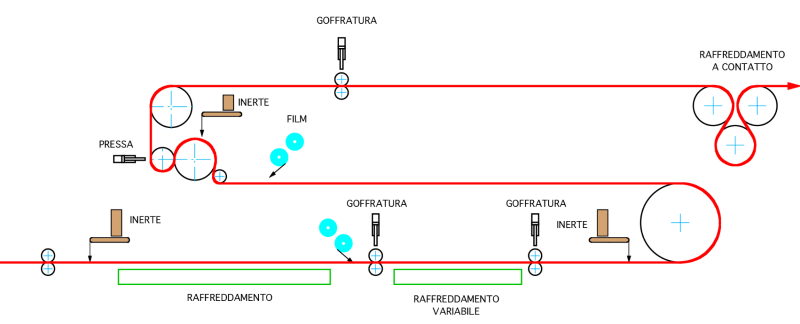

The main and common feature is certainly the simplicity of the operating concept. It is a matter of completely finishing the treatment of a surface, moving on to the treatment of the second and then cooling.

The validity of this system is easy to understand: with the exception of slate products based on SBS, for which it is necessary to equip the line with an additional inversion group, there are no longer any changes to the path for all the other productions, indeed in many cases they it is not even necessary to stop the line.

Obviously, just analyzing the path of the figure, all the products on the market today are feasible, including bi-sanded and sanded slate.

The embossing stations and the variable cooling system allow excellent results even with loaded or thin pro-ducts.

This system was created for the first time in 1994 in the USA and was later consolidated thanks to subsequent installations.

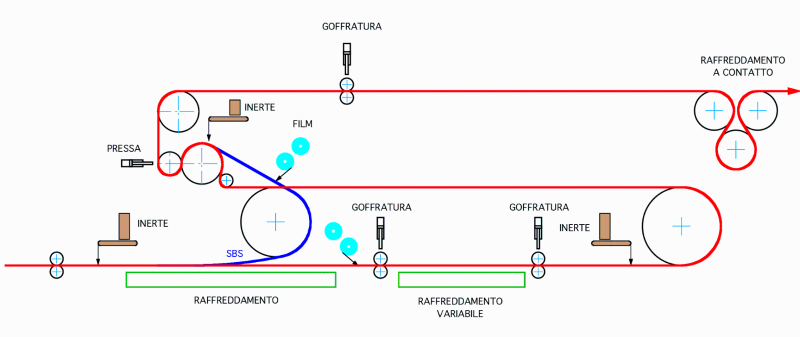

The main and common feature is certainly the simplicity of the operating concept. It is a matter of completely finishing the treatment of a surface, moving on to the treatment of the second and then cooling.

The validity of this system is easy to understand: with the exception of slate products based on SBS, for which it is necessary to equip the line with an additional inversion group, there are no longer any changes to the path for all the other productions, indeed in many cases they it is not even necessary to stop the line.

Obviously, just analyzing the path of the figure, all the products on the market today are feasible, including bi-sanded and sanded slate.

The embossing stations and the variable cooling system allow excellent results even with loaded or thin pro-ducts.

This system was created for the first time in 1994 in the USA and was later consolidated thanks to subsequent installations.